Camshafts are the central building block for every engine, it will determine your heads, intake, carburetor, exhaust, pistons, valves, and more. The problem, though, is that we see big numbers and think more power but never stop to ask ourselves what will take to provide adequate airflow through the motor. We purchase a large cam and throw it into the motor without understanding all of the limits the rest of our components have. With all the components lacking, we end up with a mild motor instead of the monster we were hoping for. Rather, we need to choose every component based on the cam’s potential and, to decipher its air needs, we must understand the terminology. Let us dig in!

Cam Shaft Arrangements

Modern camshafts have three primary arrangements: overhead-valve (OHV), single overhead cam (SOHC), and dual overhead cam (DOHC). Both single and dual overhead cam can be combined as, simply, overhead cam (OHC). Each has distinct advantages and disadvantages and OHVs are slowly being phased out for their overhead cam counterparts. Many manufactures have embraced the complexity and versatility of OHC systems but you will find a few manufactures that will use the old OHV system.

Over Head Valve

Overhead valve systems are becoming antiquated but they exist in a realm that most engine builders enjoy. V8 engines of 1960s and early 1970s produced ungodly amounts of power all from OHV cams. A single cam, located in the engine valley, drove every valve on the engine. Pushrods and lifters connected your cam to the rockers, and breathed life into car. You can still find this system today in many sports cars and trucks including the 2020 Corvette.

Advantages

With the cam located in the central valley of the engine, car manufactures can build a compact motor with a low center of gravity. The complexity of the system is also lower and often produces engines that will last for well over 250,000 miles. With the lower complexity, they can be produced for low cost but you will rarely see this savings passed on to the consumer.

Disadvantages

The simplicity does come with a cost associated with it in the form of less valve lift control, pushrod flex, and poor high RPM performance. OHV motors have distinct disadvantages with valve lift, due to the indirect drive of the rocker arm and its inability to effectively vary valve lift and duration. As RPM’s spin up you will find that the pushrods begin to flex creating poor valve performance and potential risk to bending a push rod. Hydraulic lifters will begin to float and it will become difficult to open and close the valves consistently. All of this will lead to poor high RPM performance and potential engine damage.

Overhead Cam (OHC)

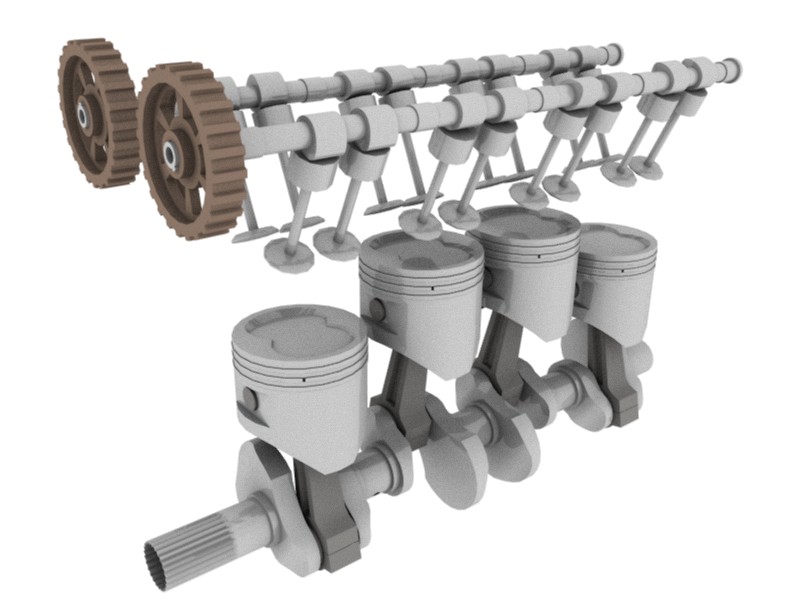

Overhead cam motors have taken over the automotive industry and for excellent reasons. OHC motors are efficient and allow for complex variable valve systems that boost both performance and fuel economy. The proximity of the cam to the valves allows the cam to drive the rocker arms without the use of pushrods and lifters. With the cam driving the valves you don’t have to worry about pushrod flex or floating your lifters, allowing you to push the motor to greater RPMs.

Single Overhead Cam (SOHC)

SOHC uses a single cam at the top of the head. With a V8, you will have a single cam at each head but this is still considered a single overhead cam. A large timing chain or belt is used to reach the top of the head and drive the cam.

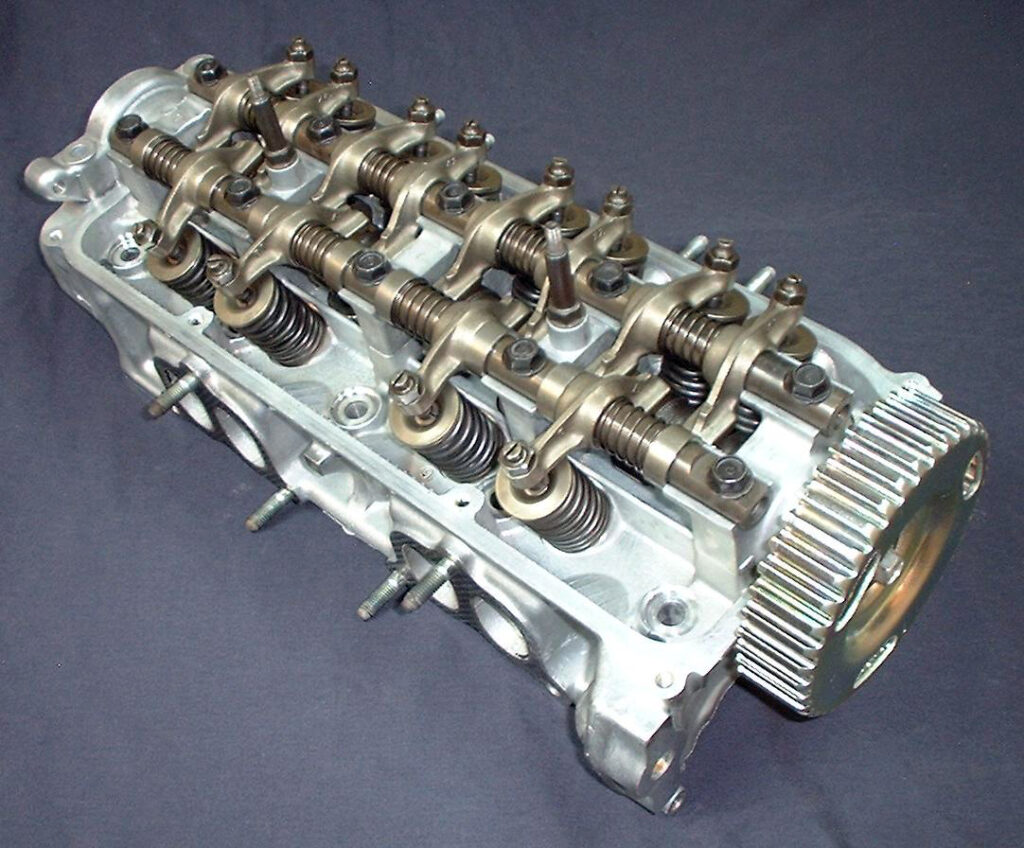

Dual Overhead Cams (DOHC)

DOHC uses two camshafts per head. One drives the intake valves while the other drives the exhaust valves. For DOHC the belts or chains get even larger as they now must drive a second camshaft.

Advantages

OHC becomes more complex, but this is to our benefit as we can now control valve lift to a greater degree. Variable valve lift allows us to create more efficient engines that still pack a serious punch. Direct drive of the rockers allows higher RPMs where we can take advantage of bigger cams. In turn, we can also increase our high-end torque and provide more horsepower to race your buddies.

Disadvantages

As the complexity of the engine increases so does the amount of components needed to run everything. This adds weight and size to the engine and puts more of that weight on the top of the motor raising the center of gravity. If the motor runs a timing belt, it will have to be replaced at a recommended interval throughout the life of the motor. In the case of failure, the damage tends to be more catastrophic and costly to repair. Despite these problems, the benefits outweigh the disadvantages and most manufacturers now use OHC engines.

Terms You May Need to Know

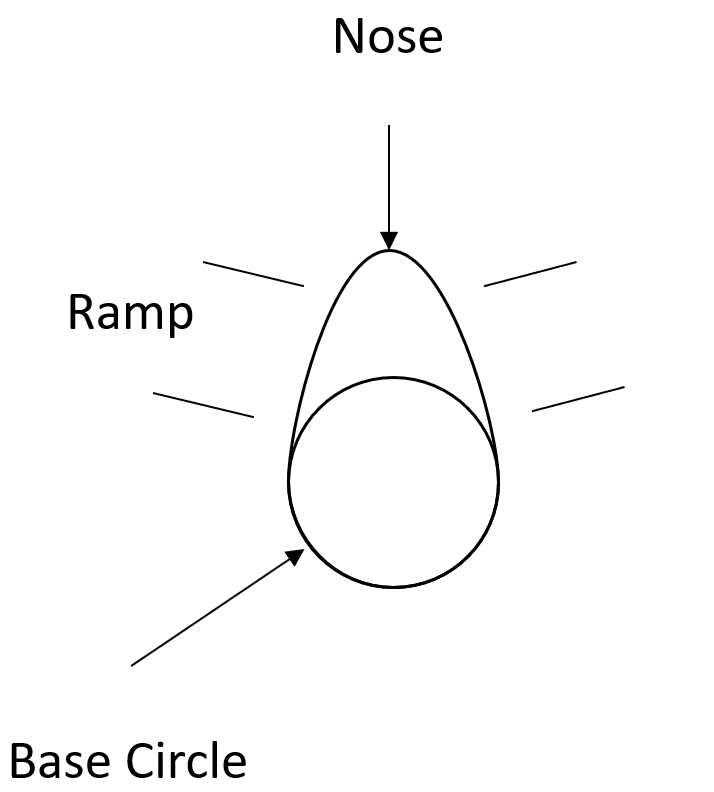

Ramps

Profile of the cam that initiates lift and descent of the valves.

Nose

Lobe at the highest maximum lift point where the valve remains open for the longest duration.

Base Circle

Where the valve is at the closed position.

Symmetrical

Cam design where each half of the cam, split at the peak of the nose, meaning it is the same on both sides.

Asymmetrical

Cam Design where each half of the cam, split at the peak of the nose, is not the same on both sides.

Flat Tappet Cam

A flat tappet cam uses a “flat” surface to contact the cam profile. This surface is not actually flat but rather rounded to allow the lifter to rotate and wear in properly. These lifters can be hydraulic or mechanical.

Roller Cam

Roller cams have a roller attached to the base that runs against the cam. Each set of lifters, intake and exhaust, will have to be tied together to prevent them from rotating. Otherwise, the lifter could turn perpendicular to the cam and the roller would cease functioning.

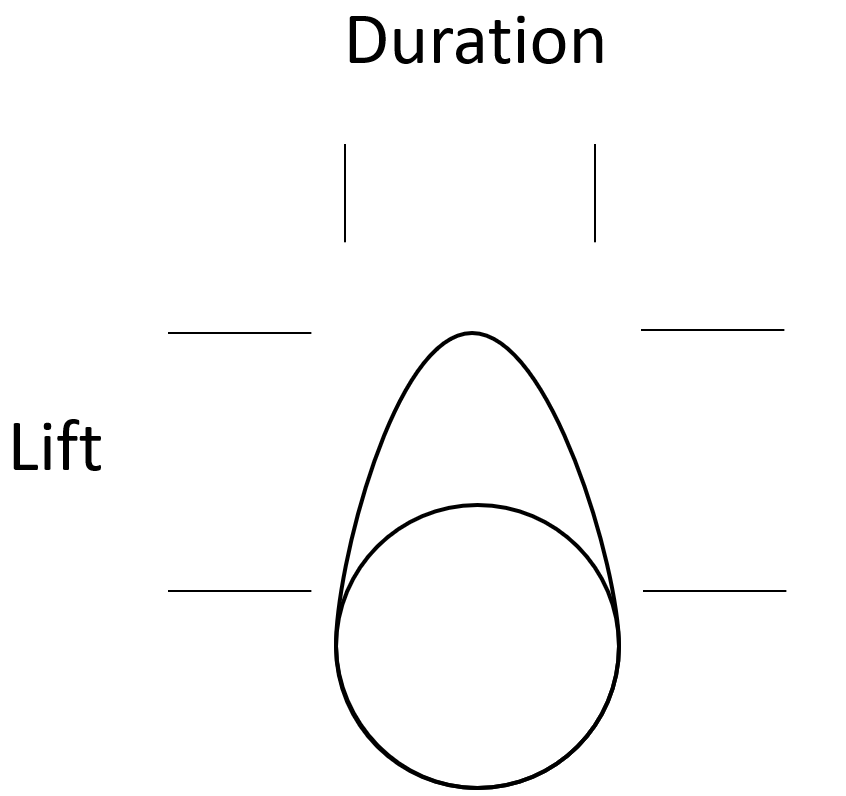

Lift and Duration

Cam Lift

Cam lift is the amount the cam lobe rises from the base circle. This determines how much lift will be given to the valve and determines valve lift based on the rocker arm ratio. To calculate the total valve lift, use the following formula:

Valve Lift = Lobe Lift x Rocker Arm Ratio

Another useful formula for finding lobe lift is:

Lobe Lift = Valve Lift / Rocker Arm Ratio

How does this affect performance?

In theory, more lift will allow the engine to draw in more air and fuel, which, will produce more horsepower. However, we must also upgrade the rest of the engine components to allow adequate airflow in and out of the motor to take advantage of the increase in lift. As we increase lift we will also need to pay close attention to the gap between the open valve and the piston otherwise we may create a situation where the valve strikes the piston. If the valve comes in contact with the piston, it is game over.

Lobe Duration

Duration is the amount of time the valve stays open, from the moment it reaches .050” until it closes to .050”, measured in degrees of camshaft movement. The industry has adopted this .050” as the standard for measurement, however, you will find some companies trying to cheat their numbers by using different open and closed distances.

At high RPM increased duration allows the engine to produce more power by pulling in more air and expelling more exhaust. Duration also affects the RPM range, of the cam, and will allow you to tune the engine to a specific RPM to produce power. As we increase duration we will exchange high-end power for low cylinder pressures and poor low-end power production.

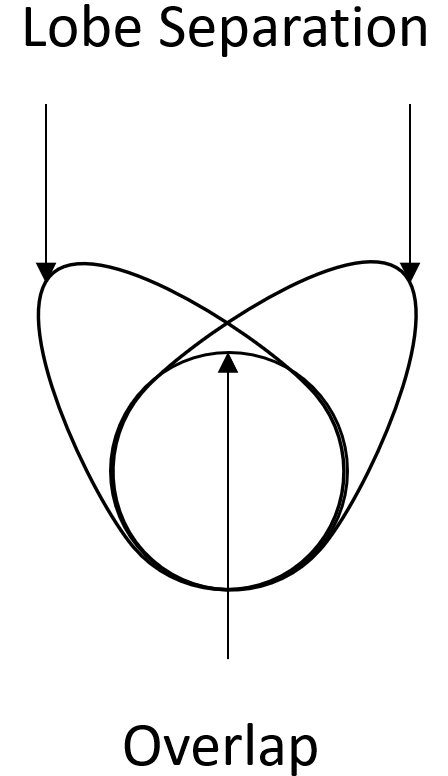

Lobe Separation and Overlap

Lobe Separation

Lobe separation is the distance in degrees from the top center of the intake to the top center of the exhaust lobes. Lobe separation affects the amount of overlap your cam will have and will determine your peak torque, peak horsepower, and the quality of your power curve.

Overlap

The point at which both intake and exhaust are open at the same time is called overlap. The overlap between the intake lobe and the exhaust lobe will contribute to exhaust scavenging effects at high rpm. However, at low RPM you will find a state of low vacuum and poor engine performance, as exhaust gasses are not ejected from the cylinders. The effect of these trapped gasses will cause the engine to “build up” creating a need to “clear” the cylinders. This overlap is also what gives cars the distinct “lope” sound of a high performance motor.

Timing

Cams can be advanced or retarded to shift the torque curve on the RPM scale. You will observe this most often in racing applications where competitors are trying to get every bit of performance out of their cars. If you experiment with this, however, you should be careful with your piston to valve clearance as you will shift the valves closer to the pistons. In general, advancing the cam will build low-end torque and retard the cam and you will create more high-end power. Modern cars use variable valve timing to provide the best performance at any given time.

Variable Valve Lift

Engines that use variable valve lift are becoming more common in the modern era. Cams will have multiple lobes per valve, which, will engage the rocker arms at predetermined points. At each defined event, the computer will signal a valve to open. This will allow oil to flow through the rocker arm bar, to the rocker arm, where a pin will engage activating a second section of the rocker arm. Each section of the rocker arm will run on different profiles of the cam allowing the lift to be varied based on the need of the motor.

This is done to improve engine efficiency at normal operating RPMs but still give you that burst of power when you want it.

In the case of 3 stage variable valve timing, there is a second oil line that will engage a third piece of the rocker arm and switch to the third lobe on the cam.

Building Power

From a pure performance standpoint, the best cams to build an excellent power curve will have narrow lobe separations but this will come at the cost of overall horsepower, poor low-end performance, and a near-complete lack of vacuum at idle. If you want a car that will idle but still give you a nice lope pick one that splits the difference between a narrow and wide lobe separation.

In the end, this is a daunting amount of information to sort through, especially when you dig into the numbers. There are thousands of different cam grinds and an overwhelming amount of terms. Lobe duration’s, lift, single overhead cam, the list goes on. It can be confusing and this is only the start of the information we need to make a competent engine build. Cams are the central component and should be the starting point on every build. All other components will extend out from this point whether you have a classic V8 or you are tricking out your Honda Civic. A solid foundation will fortify the next engine you build. I wish someone was in my corner explaining all of this information when I started playing with engines and I want to share as much of my knowledge as I can, with you.

Thanks for reading! If you like this article check out our article on engine balancing here.

Additional Resources

YouTube video on camshaft lift and duration here.

YouTube video on DOHC, SOHC, and OHV here.

YouTube video on variable valve lift here.

Information on cams from lunatipower.com.

Information from Summit Racing on camshaft duration here.